Resins for 3D Printing: How to Choose a Right 3D Printed Resin

Where 3D Printing is concerned, there are several methods that are used to create new products. Each of these methods uses unique raw materials that have been created with this exact purpose in mind. One of the most widely used raw materials in 3D Printing is called Resin.

Resin is a liquid polymer material that is converted from its aqueous state into a solid shape through a number of reactions in 3D printing. We will explore the resins used in 3D printing, the types that exist, their benefits and drawbacks, and the things you have to consider when selecting them. If you have been thinking of getting yourself a portable 3D Printer, then this is the article for you.

Types of Resins for 3D Printing

There are about five different types of 3D Printing resins in use with the current level of technology. Each is designed to create different types of products, and each has its unique appearance. The 5 include the following.

This is the type of resin that comes with a smooth surface finish without any bumps or scratches. It offers excellent quality at very low prices and is what many people looking for a low-budget resin material for mass production go for. The resin is available both for products that need support and those that don’t, with any extra protrusion able to be rid of using tools like sanding paper. Products made from standard resin exhibit a high level of details, are translucent in nature, smooth to the touch, and are easy to paint over in post-processing.

Gray Resin

Gray resin used to be known as Prime Gray, and it produces some of the smoothest 3D printed products you will ever come across. What makes gray resins truly stand out is the availability of colors; they range from grey, black, yellow, brown, orange, red, green, blue, and red. The surface of gray resin-made materials is also easy to paint, and they come in handy when making high-quality toys and objects. If you are ever in need of making figurines of your favorite characters, then gray resin is what you should be going for.

Mammoth Resin

Just as the name implies, mammoth resin is the best type to go for when printing huge materials in one go is what you are going for. It comes with huge dimensions that usually stand at about 2100 by 700 by 800. They are majorly made from liquid resins that have been hardened using a laser. The surface of the materials made from mammoth resin is smooth but a little complicated. For this reason, the applications of mammoth resins are a little constricted.

Transparent Resins

This is the most popular resin type since people love creating transparent products for a range of uses. They are generally resistant to water and are the best options for small objects that need to be smooth, high-quality and stiff. Their tiny sizes make this method the ideal one for flexible printing and mass production. There is more room to create anything you want without wasting too much material.

High-Detail Resin

This is a unique type of resin that’s a little different from the rest; instead of the normal stereolithography process, it uses another more recent 3D printing technology called the PolyJet. It works by injecting ultra-thin jets of resin layers onto a building platform, where the layers are immediately hardened by UV light. That process is repeated layer by layer until the entire product is finished. The high-detail resin is what you go for is enormous levels of details are what you are looking for. Even the most minuscule of details will be printed as it is.

Advantages and Disadvantages of using Resin for 3D Printing

There is no downplaying the impact that 3D printing has already had in the world of manufacturing, and more is still expected from it as advancements continue to rack up. Resins play a significant role in this growth; the following are the strengths and the weaknesses of using resins for 3D printing.

Advantages

- Resin-based prints have better resolutions, and they look much better and more detailed than any other raw material used in making 3D prints. The laser technology used in the process is precise and recreates a model with very minimal margins of errors.

- The printing process is much faster where resins are involved compared to using filaments. In the FDM system, the extruder has to move around the print bed to drop the aqueous filament, and this takes too much time. In resin-based printers, the laser does all the work without moving around much, curing and hardening the product simultaneously.

- Products made from resin are durable, more robust, and look much better than those made from FDM processes. The treating method used for resins makes the products to be more robust as the bonds are more reinforced every time a layer is laid down. In a nutshell, you don’t have to wait for the product to be ready for the hardening process to be done; by the time the product is finished, all the treatment processes are also done.

Disadvantages

- Resins are expensive, and this is not a surprise. Owing to their efficiency, it goes without saying that the cost of creating them is also high as it involves quality raw materials and complicated processes. An FDM 3D printer is about $300, while the cheapest resin 3D printer right now is more than $1000, with a good number of them hitting the $3000 mark. Resin liquid itself is also costly and not that widely available.

- Resins are not that flexible as the resultant products. Printing with resin has to be done from a single var of resin without mixing it with another solution; this is the only way to ensure that uniformity is attained. This may be good for the quality, but it limits the number of ways someone can design and get the best out of their 3D printer.

- The post-processing part of dealing with resins is a bit complicated and requires a professional for the best results. The support structures have to be removed delicately, sand polished, and painted in a way that doesn’t interfere with the original surface of the product. This can be time-consuming for a beginner, and they are most likely to mess up if they do it alone.

- Handling resin without wearing gloves is very dangerous. The entire process should be done in a room that’s well ventilated, and you have to wear a mask while at it. The chemicals used in the manufacture of resins are known to interfere with the nervous system if someone is exposed to them for too long.

- The availability of 3D printers that use resin and even the resin itself is poor. Not many shops stock them up due to their high costs. They rarely leave the shelves compared to FDM-based printers. The community of people using resins is too small, and this has hampered the distribution of the product. Things will change the cheaper they become in the future.

What to Consider when Choosing a 3D Printer Resin

When it comes to choosing resin for your 3D printing needs, you have to pay attention to some factors based on two broad lines: by materials and by application. When it comes to materials, the following considerations should feature highly on your priority list.

- Tensile Strength: This is the resistance of the resin material when subjected to high tension. The higher the tensile strength, the stronger the resulting object. This is how an object made with resin attains durability.

- Elongation: The resin should be able to stretch without breaking when pressure is applied to it. This enhances the flexible properties of the end product, giving them rubber-like properties.

- Water Absorption: Water undermines the structural integrity of products made from resin, and to the end, make sure the resin you are choosing is water-resistant to avoid affecting the material properties.

- Quality of Finish: Some resins will create smooth finishes, while others will produce finishes that are coarse with visible patterns. Depending on what you want, you have to know that the end product is influenced by the type of resin you chose to go with. Therefore, do your homework right to know the properties of what you are getting in advance.

- Durability: Resins have been engineered to produce tougher models, but not all of them are the same. You have to go for resins that possess the tensile strength and elasticity that can hold for long even when used to create a product that has many moveable parts and joints.

- Transparency: If you want to create transparent objects, then you have to stay clear of resin types like gray resin or mammoth resin. The best option for you would be transparent resin. The same applies for the reverse; the end product does play a huge part in determining the resin needed. Therefore, use that line of reasoning in your search.

- Costs: As previously mentioned, resins used in 3D printing are not cheap. Quality resins go for over $50 per kilogram, and that may be way above the affordable range of many people who are looking to experiment a lot with their 3D printers. If you have to go with resins, make sure you have figured out what you want to make early on, or you may end up wasting valuable resins making damaged prints.

Recommended 3D Printer Resin Brands

There are a number of resins that are used in 3D Printing in the market that would be of great interest to anyone looking to buy one. With so many resin brands putting their own version, the following are the standout resin products that you should be paying attention to.

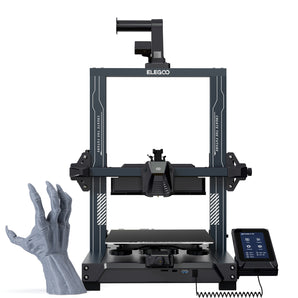

ELEGOO Standard LCD UV-Curing Photopolymer Rapid Resin

Going for $34.99 per kilogram, this resin is packed in a bottle and comes in a variety of colors. The polymer changes its physical attributes the moment it comes into contact with light, hardening immediately the layer is laid down, saving you the time you will need the product to be treated before using it. Some of the stand-out features include the following.

- High precision and low shrinkage

- Fast curing

- Great stability

- Bright color options

- Versatile applications

- Safe

ELEGOO Water Washable Rapid Resin LCD UV-Curing Resin

Washable resins are the most convenient in the market as they don’t need complicated processes to clean the final product, you simply drop them inside a vat of water and shake until the excess resin is washed off, leaving behind a solid object. It is compatible with a huge number of 3D printers and reacts very fast with LED lights to give amazing details. Some notable features include the following.

- Secure packaging

- Fats curing

- Stable

- Low shrinkage

- Great precision

- Wide application

ELEGOO ABS-Like LCD UV-Curing Photopolymer Rapid Resin

This is a VOC-free resin that also reacts very quickly to light, hardening up the moment the layers are laid down. You only need to expose it to UV light from a lamp or direct sunlight. They irradiate UV light which works towards photocuring the resin making it the final product safe for use immediately. The following are some of the stand-out features.

- Light odor

- High tenacity

- Low shrinkage and high precision

- Wide applications

Resin vs. Filament

Resin and Flimanet polymers are the two of the most commonly used materials for 3D printing. Each is unique in its own way and the products they each produce are a little different when it comes to quality and appearance. The following are ways through which they differ from each other.

- Transparency: Resin is the only polymer that can produce transparent 3D products so far, and this gives it an edge over Filament polymers. The latter is, however, decent at producing normal objects of varying colors.

- Range: Filament users have more range when it comes to color varieties and customizations; the polymers can be mixed with other materials to create blends that make the end products look even better. Resin, on the other end, is limited in terms of range, with most of it being proprietary, limited to a certain type of printer.

- Precision: Resin takes the crown for precision and smoothness as they use a laser-based setup. Filament polymers, on the other hand, make use of a nozzle that does produce high-quality products but not as sharp as those made using resin.